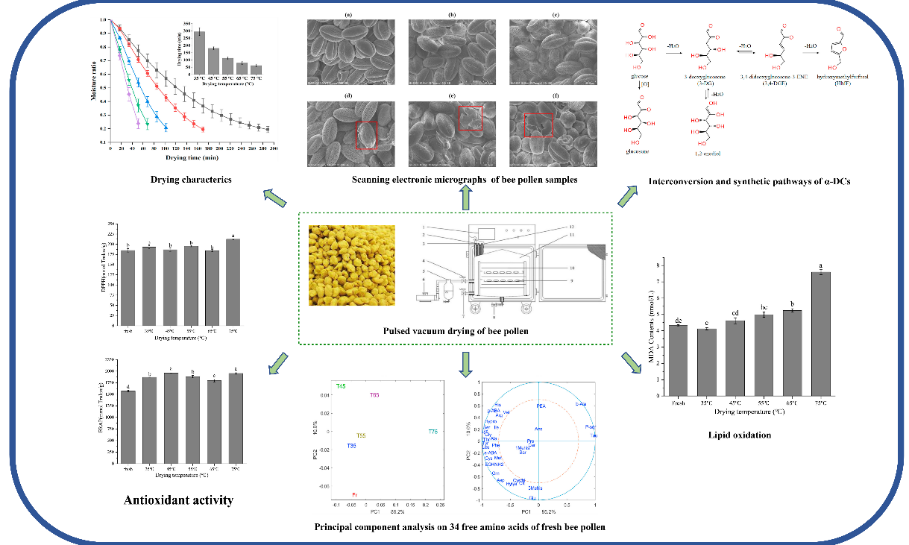

A study revealing pulsed vacuum drying characteristics of bee pollen and regularity of its quality change

Date:2022-10-27

The Institute of Apicultural Research of Chinese Academy of Agricultural Sciences (IARCAAS) recently studied the effect of pulsed vacuum drying temperature on the drying characteristics, physicochemical properties and microstructure of bee pollen and the regularity of quality change. Relevant findings were published online in LWT-Food Science and Technology.

Fresh bee pollen is susceptible to microbial contamination after being harvested due to its high water content (20-35%) and rich nutritional content, which results in quality deterioration and reduction in added value. Drying is one of the most effective methods to solve these problems, and facilitates to improving the quality and added value of bee pollen products. However, high temperature and oxygen contact may affect the lipid status of bee pollen, leading to lipid oxidation, quality deterioration and reduction in added value. During the process of pulsed vacuum drying, the low oxygen environment could effectively inhibit oxidation reaction, prevent color deterioration and reduce the loss of biological activity.

This study explored the effect of different pulsed vacuum drying temperatures on drying kinetics, amino acids, toxic products of Maillard reaction (α-dicarbonyl compound and hydroxymethylfurfural), antioxidant capacity, lipid oxidation and microstructure, and analyzed transformation and synthetic pathways of 5-hydroxymethylfurfural and α-dicarbonyl compound. According to the findings, at the drying temperature of 55°C and above, dried bee pollen showed significant changes in the shape and surface structure compared with fresh bee pollen, with large amounts of α-dicarbonyl compound and hydroxymethylfurfural. Meanwhile, dried bee pollen showed a notable decrease in amino acid content. Pulsed vacuum drying increased the antioxidant activity of bee pollen, but its high temperature accelerated lipid oxidation. As 3,4-dideoxyglucoson-3-ene was taken as a representative indicator for the safety of bee pollen, the bee pollen drying temperature should be controlled below55°C. The findings provided a theoretical basis and scientific guidance for improving bee pollen dry processing and product quality.