Propolis ethanol extract functionalized chitosan/Tenebrio molitor larvae protein film for sustainable active food packaging

Date:2024-09-18

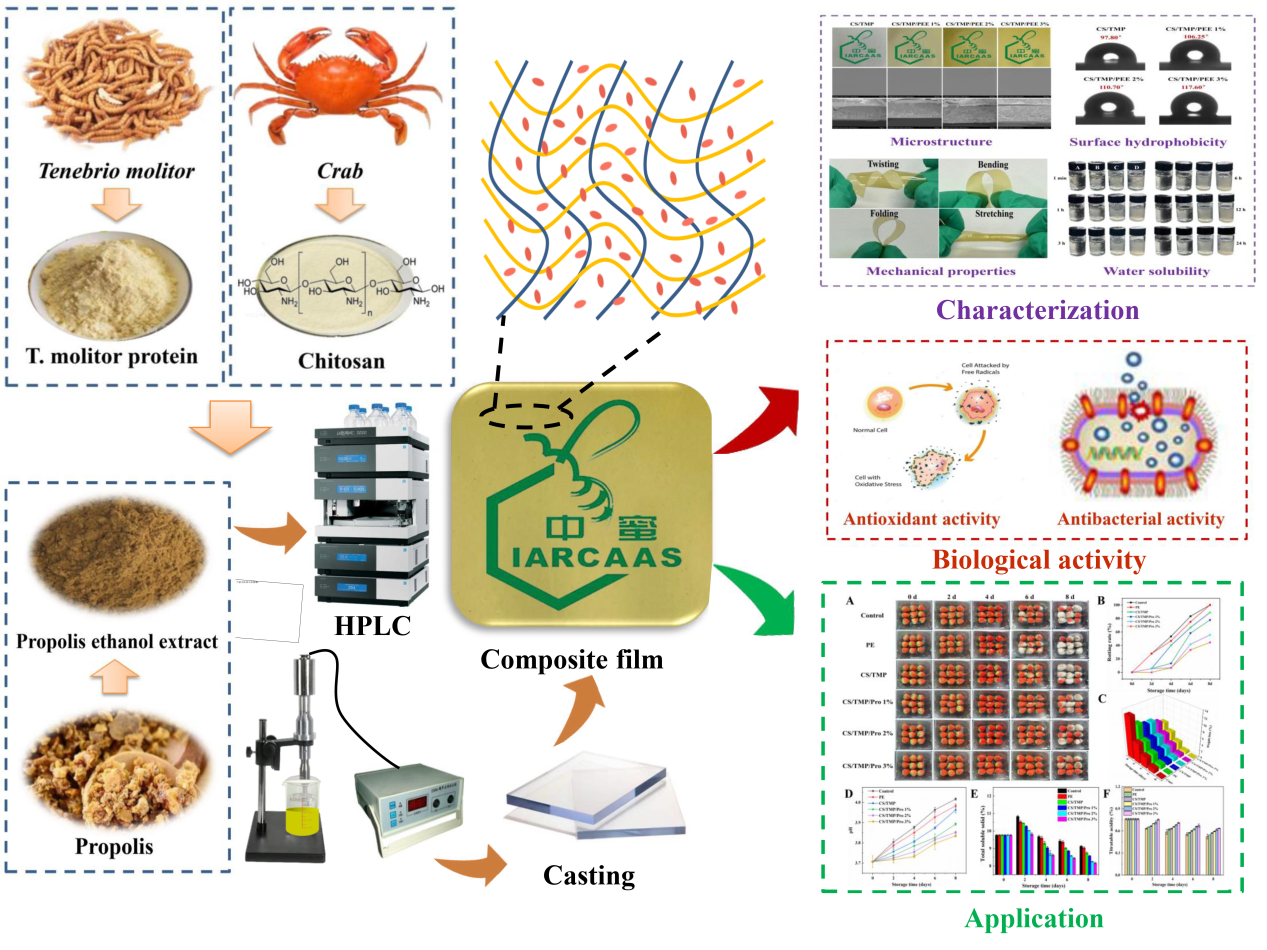

Recently, the Resource Insect Product Processing and Functional Evaluation Team at the Institute of Apicultural Research, Chinese Academy of Agricultural Sciences, developed sustainable active food packaging materials made from chitosan/tenebrio molitor protein loaded with propolis ethanol extract, and explored its application in fruit preservation.

Currently, the widespread use of petroleum-based plastics has caused serious environmental impact and depletion of non-renewable resources. The selection of natural biodegradable polymers to replace petrochemical based plastics has become a research hot spot. Chitosan (CS), a naturally renewable cationic polysaccharide, is considered to be one of the best candidate materials for the production of bio-based antibacterial packaging due to its low cost and ease of industrial preparation. However, the inherent limitations and single functions of chitosan, such as poor mechanical properties and barrier properties, limit its widespread application. At present, researchers have demonstrated that cross-linking or blending chitosan with proteins can improve the performance of packaging films. Tenebrio molitor, as the first new insect resource food approved by European Union, is rich in protein and has good emulsifying, foaming and gel properties. However, we have not found the application of Tenebrio molitor protein (TMP) in active food packaging. Therefore, in this study, chitosan was chose to combine with TMP to prepare active food packaging materials. In order to further improve the performance of the composite membrane, especially the antioxidant and antibacterial activities, we chose to add propolis ethanol extract (PEE) to the composite film of CS and TMP, so as to enhance the functional activity of the composite film and extend the shelf life of fruits.

In this study, a sustainable green antibacterial food packaging material loaded with propolis ethanol extract was developed based on CS and TMP to improve the shelf life of perishable fruits. The effects of different concentrations of PEE fillers on the structural characteristics, apparent morphology, mechanical properties, physicochemical properties, antioxidant activity and antimicrobial activity of functional films were determined. Finally, the preservation performance of CS/TMP functional composite films and commercial polyethylene (PE) film were compared with strawberries, and the potential of functional composite film as a food packaging material for fruit storage and preservation was explored. The incorporation of PEE make the composite film exhibit excellent visible light transparency, mechanical properties, water vapor barrier properties, thermal stability, biodegradable properties, as well as strong antioxidant and antimicrobial activities, which are enhanced with the increase of PEE content. In addition, the functional composite film prepared in this study can effectively extend the shelf life of strawberries and achieve the preservation of strawberries. Therefore, the composite film loaded with PEE, as a potential green active packaging material, not only expands the application of TMP in the food packaging industry but also has broad application prospects in the post-harvest preservation of fruits and vegetables.

This work was funded by the National Natural Science Foundation of China and the Agricultural Science and Technology Innovation Program of the Chinese Academy of Agricultural Sciences.

The DOI Link of the original text: https://doi.org/10.1016/j.carbpol.2024.122445

By Xiangxin Li (lixiangxin@cass.cn)